CLOSED

Main application

Used for car trunk cover board, trunk clapboard, trunk carpet substrate, side wall decortation board, ceiling etc. interior place. Used for manufacturing different kinds of high strength packing box

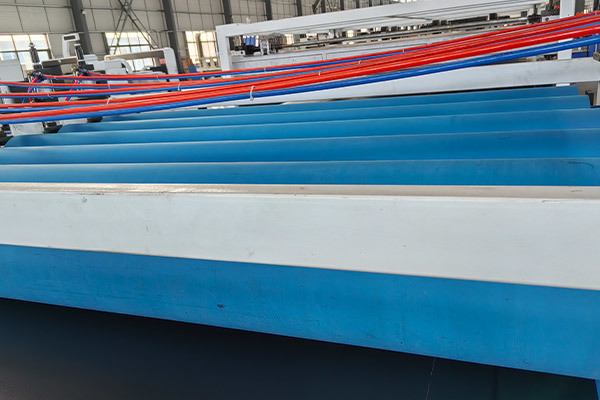

PP honeycomb board through extrusion method made three layers sandwich board of one time forming, two sides is thin surface, middle is honeycomb structure; According to honeycomb structure can divide into single layer, double layer board. PP honeycomb board also can one time forming, coat fabric at two sides, leather, with light weight and high strength, non-toxic, environment, shake absorption and cold-resistant, soundproof& heat preservation, moistureproof& heat insulation etc. advantage.

Technical parameters

Model | Suitable material | Products width(mm) | Products thickness(mm) | Capacity(kg/h) |

JSD75/75/75 | PP | 1200-1600 | 2-12 | 350-450 |

JSD100/100/100 | PP | 1200-2000 | 2-20 | 600-700 |

Note: Informations listed above are for reference only, the production line can be designed by customer’s requirements. | ||||

|  |  |  |  |

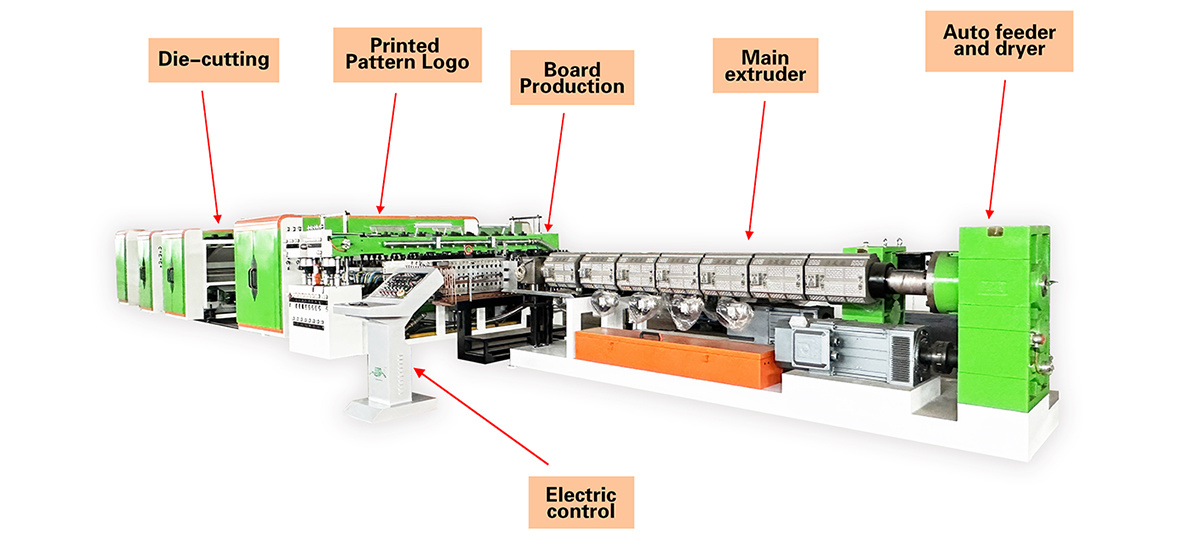

Step1 Host Heating Plasticizing | Step2 Mold Shape into a Hollow Shape | Step3 Host Stereotyped Traction Leveling for the first time |

|  |  |  |  |

Step4 Printing Surface Treatment Equipment Printing Surface Treatment | Step5 Cut according to the size of the order. | Step6 Count and output the plates through the conveyor belt |

Product advantage

Good Environmental Protection Performance and secondary processing performance, can be processed into the turnover box, packing box and so on.Its process is simple, low cost and high efficiency. Good Environmental Protection Performance and secondary processing performance, can be processed into the turnover box, packing box and so on.It is suitable for large-scale industrial production and transfer packaging of fruits, vegetables, frozen seafood and other products.

|  |  |  |  |

Step1 Host Heating Plasticizing | Step2 Mold Shape into a Hollow Shape | Step3 Host Stereotyped Traction Leveling for the first time |

|  |  |

Step4 Printing Surface Treatment Equipment Printing Surface Treatment | Step5 Cutting Fixed length Cutting |

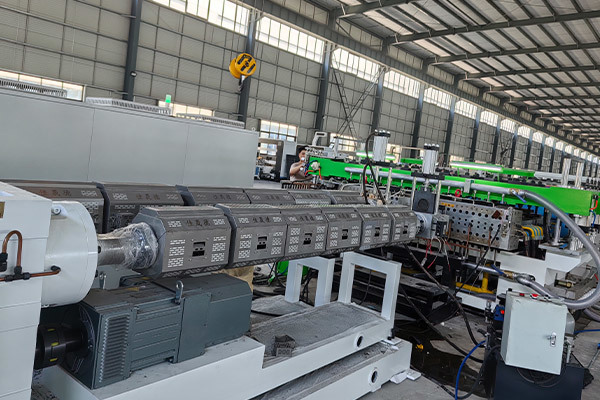

Production line composition

● Products features and application introduction

● Recommend suitable processing technology

● Offer information consultacny

● Offer testing methods and production technology standard Machinery Production

● Offer the machinery installation required conditions

● Could change the solution modification without notice

● Study and solve technology situation and materials formulation together

● Offer installation and worker training

● Establish and record customer document

● Offer spare parts to assure the machine maintenance and stable production

● Offer necessary technique support for the new machinery

● Regularly visit customers and collect feedback

● Promise of one year quality guarantee, lifetime guarantee of machine maintenance